Mathata a ho emisa koloi - mokhoa oa ho fumana, ho felisa

Tse ka hare

Haeba ho na le matšoao a deformation, likarolo tse ngata li tlameha ho nkeloa sebaka: li-axle, lihlahla le li-levers tse ka holimo / tse tlase, li-ball bearings, li-blocks tse khutsitseng, lithaere, liliba, li-anthers, li-hinges, lishiti tsa torsion bar, valve ea compression, litiiso tsa stem.

Haeba ho se sebetse hantle ha ho emisoa ha koloi ho fumanoa, ho potlakile ho etsa tlhahlobo e felletseng ea koloi. Ke ho lokisoa ka nako feela ha likarolo tse tsofetseng ho ka netefatsang leeto le bonolo le le se nang mathata.

Ke hobane'ng ha ho fanyeha ho robeha ka koloing

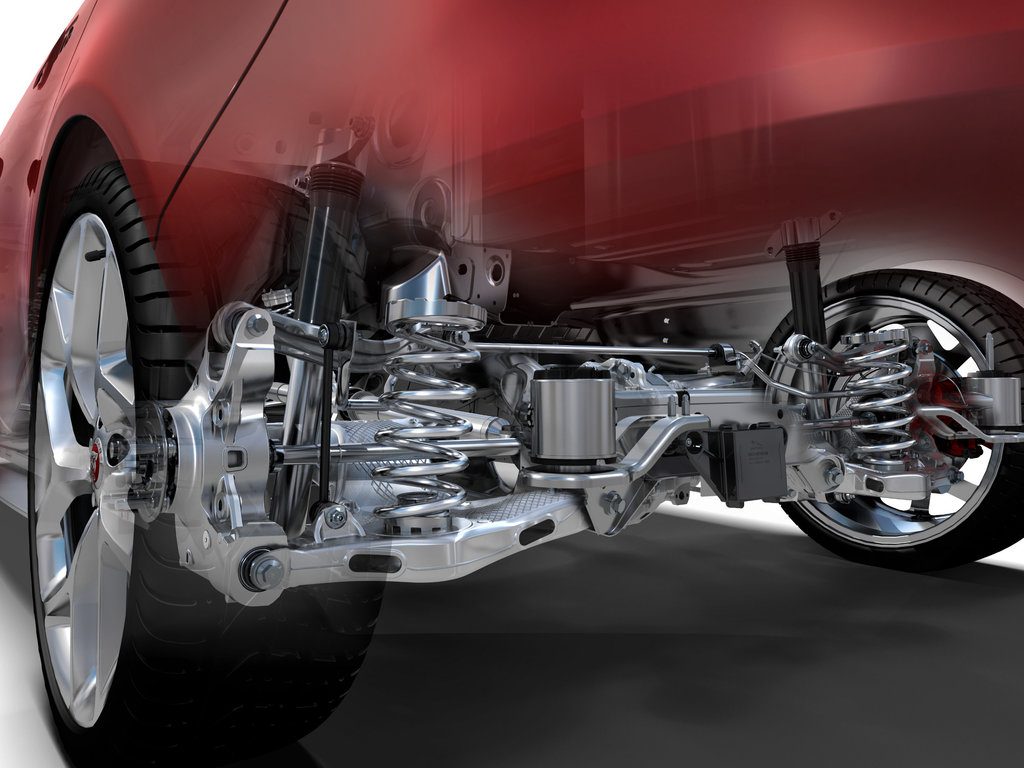

Lisebelisoa tsa lisebelisoa tse mathang li na le lithupa tsa stabilizer, li-absorbers, li-blocks tse khutsitseng, liliba le lihokelo. Mekhoa ena kaofela e kopanya 'mele le mabili hore e be sethaleng se tloaelehileng, ho fana ka koloi ka botsitso le ho tsamaea hantle tseleng. Nakong ea ho sisinyeha, lihlopha tsena tse emisitsoeng li pepesehetse tšusumetso e matla ea tikoloho le meroalo e tšosang, e lebisang ho apara ka potlako.

Karolelano ea bophelo ba tšebeletso ea yuniti ea ho emisoa ke lik'hilomithara tse likete tse 60-60. Palo ena e ka eketsoa ka makhetlo a 3 haeba u khanna ka litsela tse bataletseng, u qoba likoting le likoti. Kahoo qeto ea hore lebaka le ka sehloohong la ho senyeha ha sehlopha sena ke maeto a khafetsa litseleng tse nang le maemo a mabe a litsela. Har'a lintlha tse ling tse amang bophelo ba likarolo tsa undercarriage, tse latelang li ka hlokomeloa:

- boleng ba kopano ea likarolo;

- likarolo tsa moralo oa mochini;

- mokhoa oa ho khanna oa mokhanni.

Baetsi ba hlomella mechini e nang le li-multi-link system, elastokinematics, li-absorber tse feto-fetohang le mahlale a mang. Empa moeli oa polokeho ea mekhoa ena e rarahaneng ka linako tse ling e tlase ho feta ea mehlala e bonolo ea 90s. Sena se bakoa ke taba ea hore hona joale baenjiniere ba tsepamisitse maikutlo ho ntlafatsa taolo ea koloi, eseng ka matla a chassis. Ka hona, hangata likoloi li sebelisa lisebelisoa tse bobebe tsa alloy ho fokotsa boima ba 'mele kapa ho lekana lithaere tse kholo, tse tlase.

Ho hongata ho itšetlehile ka ho sebetsa ka hloko ha koloi. Ka mohlala, haeba u sa hloekise liliba ho tloha mobung, u se ke ua nchafatsa lera la anti-corrosion le tsona, joale likarolo tsena li tla potlakisa mafome 'me li ka' na tsa phatloha. 'Me ba ratang ho "hoholeha", ba robeha ka matla le ho fetola lebili ha ba otla sekoti, ba potlakisa ho roala ha li-anti-roll. Karolo ena e boetse e angoa hampe ke ho paka ka lehlakoreng le leholo la lateral.

Ke eng e ka pele ho suspension ea koloi

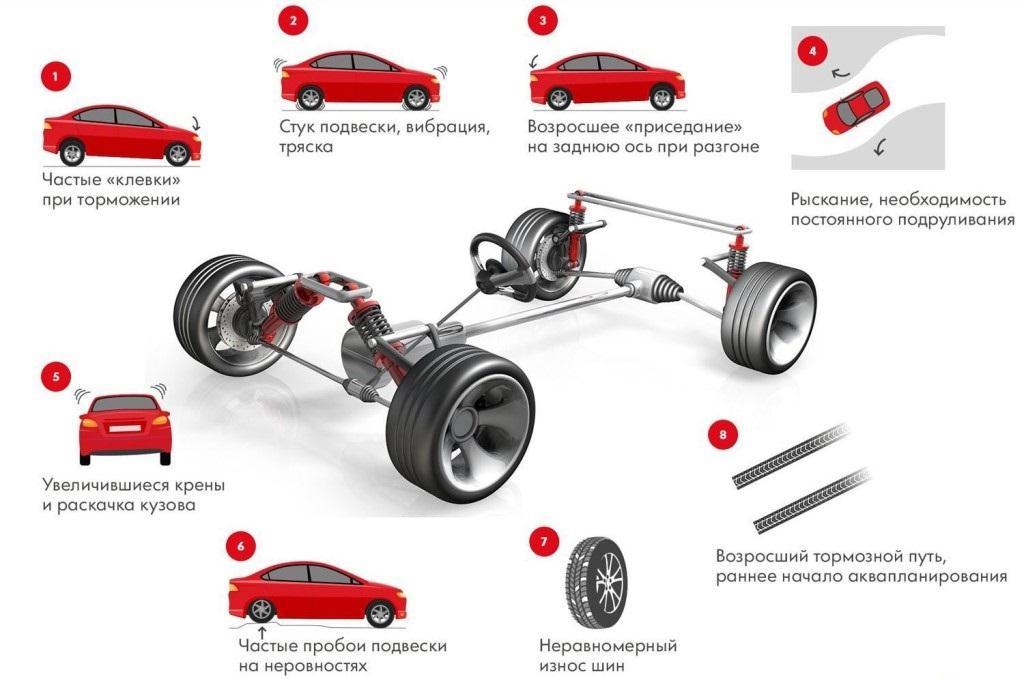

Matšoao a ho fanyeha ho robehileng

Maemong a mangata, bothata ba chassis bo ka ahloloa ka melumo e sa tloaelehang ha u ntse u khanna libakeng tse sa tšoaneng. Ho phaella moo, mokhanni o na le mathata a ho tsamaisa. Mathata a mang a ka khetholloa feela ka tlhahlobo e feletseng ea koloi (mohlala, botlolo e kopantsoeng ea bolo e tabohileng).

Matšoao a mantlha a mathata a ho fanyeha:

- tahlehelo ea tsela ea koloi ha e kena tseleng;

- ts'ebetso ea khafetsa le e sa utloahaleng ea sistimi ea ts'ireletso ea skid;

- moqolo o matla le tahlehelo ea botsitso nakong ea ho tsamaisa;

- ho thothomela ha nako e telele ha 'mele ka mor'a ho hlōla maqhubu kapa ho qhoma ka tšohanyetso;

- "Tlhaloso" ea ho fanyeha;

- ho thothomela, ho kokota le ho squeak ha u khanna tseleng e mpe le likhutlong;

- koloi e lebisa "ka ho le letšehali" kapa "ka ho le letona" ka tsela e otlolohileng;

- ho fokotsa haholo tumello ea fatše ha u laela koloi;

- ho se leka-lekane ha mabili;

- moo ho pakoang makoloi ho na le litšila tse tsoang ho mafura.

Haeba le leng kapa a mang a matšoao ana a fumanoa, ikopanye le setsi sa litšebeletso hang-hang. Ba tla etsa tlhahlobo e felletseng ea mochini mme ba nkele likarolo tse fosahetseng.

Lisosa tsa ho hloleha

Ha e le hantle, likarolo tsohle tse emisitsoeng li hloleha kapele ka lebaka la maeto a khafetsa libakeng tse sa lekanang le mokhoa oa ho khanna o mabifi. Haholo-holo haeba mokhanni a fofela ka sekoting ka lebili la setereng kapa brake pedal e tepeletse maikutlo.

Ho fanyeha ho ikemetseng

Lethathamo la "liso" bakeng sa karolo ka 'ngoe ea ho fanyeha:

- Li-stabilizer struts li hloleha ka lebaka la ho thulana le li-curbs le litšitiso tse ling.

- Li-shock absorbers li tšaba litšila. Ha e se e kene ka har'a li-anthers tsa rabara e tabohileng, e eketsa khohlano le ho senyeha ha lintho tse tsamaeang.

- Li-blocks tse khutsitseng li senngoa ke serame, mocheso le lik'hemik'hale.

- Li-hinges tsa lisebelisoa li fokotsa ho otla ka thata ho tloha ho li-bumps le tšebeliso ea rabara e tlaase.

- Liliba li na le kutloelo-bohloko ha koloi e palamisa le mafome a tsoang mobung.

Lisosa tse ling tsa ho hloleha ha suspension li kenyelletsa:

- bofokoli ba boleng ba mohaho kapa mefokolo ea sebopeho;

- tlōlo ea li-angles tsa ho kenya mabili nakong ea tlhokomelo;

- "tuning" ha e tsamaellane le melaoana.

Ke habohlokoa ho nahana hore likarolo tse ling tse fosahetseng tsa koloi (mohlala, tsamaiso ea phetisetso, mariki, mosebetsi oa 'mele, ho tsamaisa) li ka senya ho emisoa.

Mokhoa oa ho khetholla ho se sebetse hantle

Ho hlahloba ka botlalo ho emisoa le ho tseba sesosa sa bothata, koloi e tlameha ho khannoa ka "sekoting". Ebe u sheba litiiso tsohle tsa rabara, likoahelo, li-blocks tse khutsitseng, manonyeletso a bolo, li-fasteners, lipheletso tsa molamu oa thae. Haeba li senyehile, likarolo li tlameha ho nkeloa sebaka.

Haeba tumello e se e le tlase ho feta kamoo ho neng ho lebelletsoe, joale liliba li "sokolohile".

Li-blocks tse khutsitseng li hlahlojoa ka ho sisinyeha. Haeba ho se na squeak, bapala 'me tiiso ea rabara ha e senyehe, joale ntho e' ngoe le e 'ngoe e hlophisitsoe.

Ho bonolo ho ahlola boemo ba li-bearings ka mor'a ho sutumetsa 'mele oa koloi holimo le tlaase. Haeba mochine o fetoha ka makhetlo a fetang 2, joale karolo e tlameha ho fetoloa.

O ka tseba ho se sebetse hantle ha sehlahla sa tataiso le malebela ka lapel le ho thekesela ho ea mahlakoreng a rack le pinion steering wheel.

Haeba lerata le tšoanang le utloahala nakong ea ho sisinyeha, joale boemo ba mabili a mabili bo lokela ho hlahlojoa. Ha ea lokela ho bapala ha thaere e sa sotheha.

Mekhoa ea ho felisa ho robeha

Haeba ho na le matšoao a deformation, likarolo tse ngata li tlameha ho nkeloa sebaka: li-axle, lihlahla le li-levers tse ka holimo / tse tlase, li-ball bearings, li-blocks tse khutsitseng, lithaere, liliba, li-anthers, li-hinges, lishiti tsa torsion bar, valve ea compression, litiiso tsa stem.

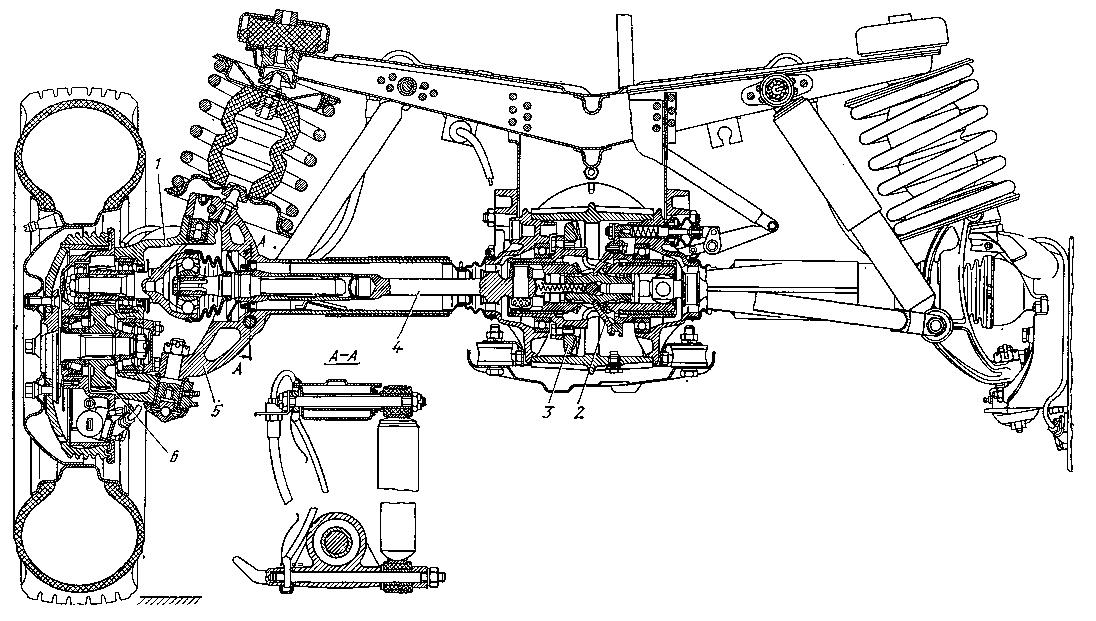

Ho emisoa ha mabili a ka morao

Empa, likarolo tse ling tsa chassis li ka lokisoa ka botsona ntle le ho kenya likarolo tse ncha:

- Haeba ho na le khaello ea lubrication lihokelong tsa rack, tlotsa likarolo.

- Haeba li-fasteners tsa "shock absorber" le piston li hlephileng, joale tiisa linate.

- Bracket e kobehileng, foreimi spar le tšiea ea 'mele - otlolla.

- Tlhaloso e fosahetseng ho li-bearings - lokisa.

- Ho se leka-lekane ha thaere - etsa phetoho e nepahetseng.

- Ho apara ka tsela e sa leka-lekaneng - Eketsa lithaere ho ea ho tse tloaelehileng.

Ke habohlokoa ho nahana hore ka lebaka la ho se sebetse ho fokolang ha koloi ho emisoa, mojaro oa li-chassis node tsohle oa eketseha. Haeba u lieha ho lokisa, ho ka lebisa ho tšohanyetso tseleng.