Sebopeho le morero oa tsamaiso ea lubrication ea enjene ea koloi

Tse ka hare

Karolo e sebetsang ea enjene ea koloi, ntle le li-unit tse palamisitsoeng, hangata ha e na li-bearings. Molao-motheo oa ho tlotsa lipara tse thellang o ipapisitse le ho li fa oli ea mokelikeli tlas'a khatello kapa ho sebetsa tlas'a maemo a bitsoang moholi oa oli, ha marotholi a emisitsoeng ka likhase tsa crankcase a fanoa ka holim'a metsi.

Thepa ea tsamaiso ea lubrication

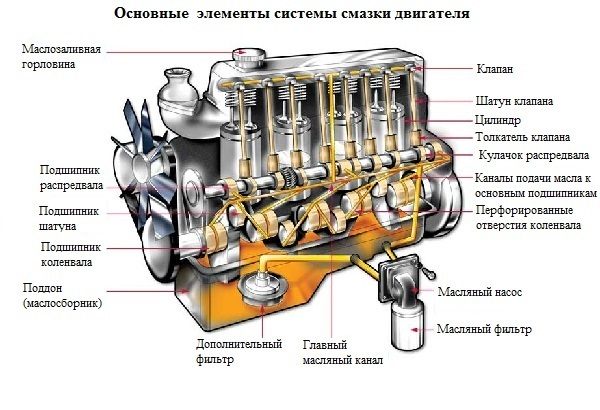

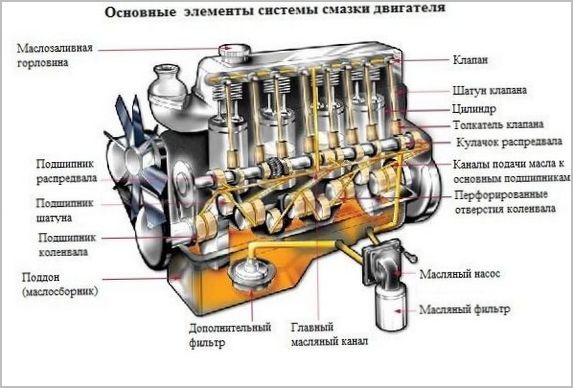

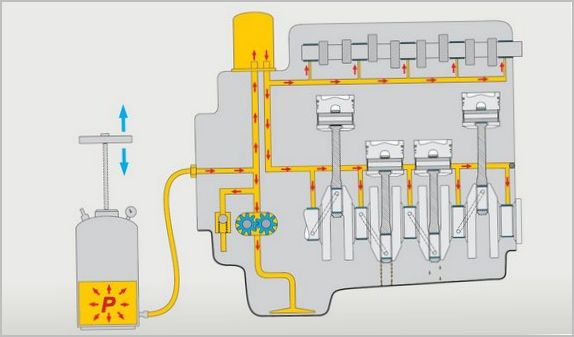

Sebaka sa polokelo ea oli se bolokoa ka har'a crankcase ea enjene, moo e tlamehang ho phahamisoa le ho isoa likarolong tsohle tse tlositsoeng. Bakeng sa sena, mekhoa le likarolo tse latelang li sebelisoa:

- pompo ea oli e tsamaisoang ke crankshaft;

- ketane, lisebelisoa kapa koloi e tobileng ea pompo ea oli;

- li-filters tse mahoashe le tse ntle tsa oli, morao tjena mesebetsi ea tsona e kopantsoe ka sefahla se feletseng, 'me letlooeng la tšepe le kenngoa ka ho kena ha mochine oa oli ho tšoara likaroloana tse kholo;

- bypass le li-valve tse fokotsang khatello tse laolang khatello ea pompo;

- likanale le lithapo tsa ho fana ka lubricant ho lipara tse khohlano;

- likoti tse eketsehileng tse lekantsoeng tse etsang moholi oa oli libakeng tse hlokahalang;

- maphegwana a ho phodisa a crankcase kapa sehatsela se arolang oli ka dienjining tse tletseng haholo.

Li-motor tse 'maloa li boetse li sebelisa oli joalo ka mokelikeli oa hydraulic. E laola li-valve clearance hydraulic compensators, mefuta eohle ea li-tensioners le li-regulator. Ts'ebetso ea pompo e eketseha ka ho lekana.

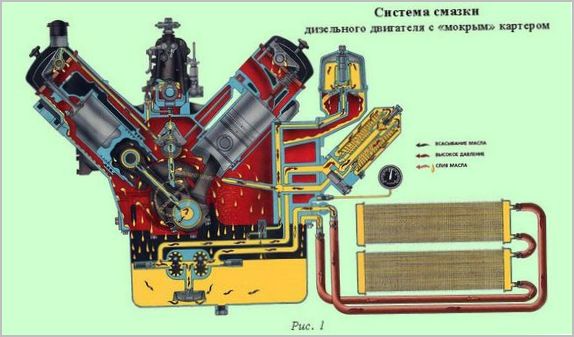

Mefuta e fapaneng ea litsamaiso

Ka mokhoa o atolositsoeng, litharollo tsohle tsa moralo li ka aroloa ka litsamaiso tse nang le sump e omileng le bate ea oli. Bakeng sa likoloi tsa sechaba, ho lekane ho sebelisa koloi ka mokhoa oa pan ea oli ea enjene. Oli e phethileng mesebetsi ea eona e phalla moo, e pholile hanyenyane ebe e hloa ka har'a mochine o amohelang oli hape ka pompong.

Empa tsamaiso ena e na le mefokolo e mengata. Koloi ha e lule e lebisitsoe ka ho hlaka mabapi le vector ea khoheli, haholo-holo ka matla. Oli e ka qhoma holim'a maqhubu, ea tloha hole le pompo ha 'mele o thekesela kapa o imeloa haholo nakong ea ho potlakisa, ho qhoma kapa ho thinya ka bohale. Sena se lebisa ho pepesehong ha marang-rang le ho tšoaroa ha likhase tsa crankcase ka pompo, ke hore, ho fofa ha melapo. Moea o na le compressibility, kahoo khatello e fetoha e sa tsitsang, ho ka 'na ha e-ba le litšitiso phepelong, e leng ntho e sa amoheleheng. Li-bearings tsa li-shafts tsohle tse kholo, haholo-holo li-turbine tsa lienjine tse chesitsoeng haholo, li tla chesa haholo le ho putlama.

Tharollo ea bothata ke ho kenya mochine o omileng oa sump. Ha e omele ka ho toba, oli feela e fihlang moo e nkoa hang-hang ke lipompo, tseo ho tsona ho ka 'nang ha e-ba le tse' maloa, tse lokolotsoeng ho tloha ho inclusions tsa khase, li bokelloa ka molumo o arohaneng ebe o tsoela pele ntle le tšitiso ho li-bearings. Sistimi e joalo e rarahane haholoanyane, e theko e boima haholo, empa ha ho na tsela e 'ngoe ea ho tsoa lipapaling kapa lienjineng tse qobelloang.

Mekhoa ea ho fana ka lubricant ho nodes

Ho na le phapang lipakeng tsa phepelo ea khatello le setlolo sa splash. Ka thoko, ha li sebelisoe, kahoo re ka bua ka mokhoa o kopantsoeng.

Likarolo tse ka sehloohong tse hlokang lubrication ea boleng bo phahameng ke crankshaft, camshaft le balancer shaft bearings, hammoho le ho khanna ha lisebelisoa tse eketsehileng, haholo-holo, pompo ea oli ka boeona. Li-shaft li potoloha libetheng tse entsoeng ke boruru ba likarolo tsa 'mele oa enjene,' me ho etsa bonnete ba hore ho na le likhohlano tse fokolang le ho ts'oara, li-liner tse ka nkeloang sebaka tse entsoeng ka thepa ea antifriction li pakeng tsa shaft le bethe. Oli e pompeloa ka likanale likheong tsa karolo e lekantsoeng, e bolokang li-shafts maemong a ho hohlana ha mokelikeli.

Likheo tse lipakeng tsa lipiston le lisilindara li tlotsoa ka ho fafatsoa, hangata ka li-nozzles tse arohaneng, empa ka linako tse ling ka ho cheka lithupeng tse hokelang kapa ka moholi oa oli oa crankcase. Maemong a ho qetela, ho koaheloa ho tla ba kholoanyane, scuffing e ka khoneha.

Ho lokela ho buuoa ka ho khetheha ka ho tlotsa li-bearings tsa turbine. Ena ke node ea bohlokoa haholo, hobane moo shaft e potoloha ka lebelo le leholo, e phaphametseng ka har'a oli e pompetsoeng. Mona, mocheso o tlosoa ka har'a cartridge e futhumetseng haholo ka lebaka la ho potoloha ho matla ha oli. Ho lieha ho honyenyane ho lebisa ho senyeha hang-hang.

Phetoho ea oli ea enjine

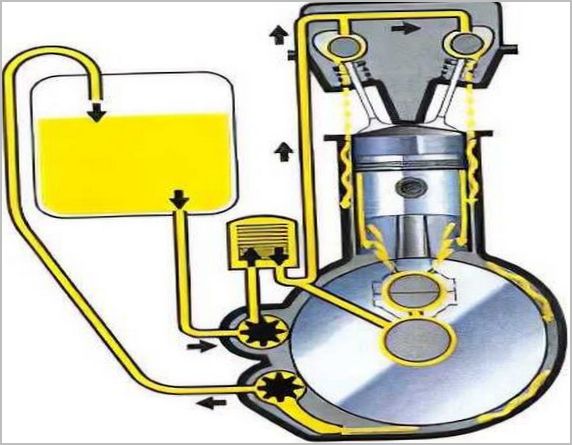

Potoloho e qala ka ho kenngoa ha mokelikeli ho tswa ho crankcase kapa pokello ea oli e kenang moo ka lipompo tsa mofuta oa "omileng". Sebakeng sa ho amohela oli, ho na le tlhoekiso ea mantlha ea lintho tse kholo tsa kantle ho naha tse fihlileng moo ka mekhoa e fapaneng ka lebaka la tlolo ea theknoloji ea tokiso, ho se sebetse hantle ha enjine kapa ho roala ha sehlahisoa sa ho tlotsa ka bosona. Ka ho feteletseng ha litšila tse joalo, ho ka khoneha ho thibela marang-rang a mahoashe le tlala ea oli sebakeng sa pompo.

Khatello ha e laoloe ke pompo ea oli ka boeona, kahoo e ka 'na ea feta tekanyo e phahameng e amohelehang. Ka mohlala, ka lebaka la ho kheloha ha viscosity. Ka hona, valve e fokotsang khatello e behoa ho bapa le mochine oa eona, e lahlela ho feteletseng ho khutlela ka har'a crankcase maemong a tšohanyetso.

Ka mor'a moo, mokelikeli o kena ka har'a sefahla se setle, moo li-pores li nang le boholo ba micron. Ho na le filthara ka ho feletseng e le hore likaroloana tse ka bakang mengoapo ea ho phunya bokaholimo li se ke tsa kena likheong. Ha filthara e tletse ho feta tekano, ho na le kotsi ea ho phatloha ha lesira la filthara ea eona, kahoo e na le valve ea bypass e tsamaisang phallo ho potoloha sefe. Bona ke boemo bo sa tloaelehang, empa bo fokotsa litšila tse bokelletsoeng ka har'a sefe.

Ka litsela tse ngata tse kholo, phallo e tlhotliloeng e lebisoa libakeng tsohle tsa enjine. Ka tšireletso ea likheo tse baloang, ho theoha ha khatello ho tlas'a taolo, boholo ba bona bo fana ka throttling e hlokahalang ea phallo. Tsela ea oli e phethela ka ho tsoa ha eona ka morao ho crankcase, moo e pholileng hanyane 'me e se e loketse ho sebetsa. Ka linako tse ling e fetisoa ka sehatsetsing sa oli, moo karolo ea mocheso e lokolloang sepakapakeng, kapa ka mochine o futhumatsang mocheso ho kena tsamaisong ea ho pholile ea enjene. Sena se boloka viscosity e lumelletsoeng, e itšetlehileng haholo ka mocheso, hape e fokotsa sekhahla sa karabelo ea oxidative.

Likarolo tsa ho lubrication ea diesel le lienjine tse jereng haholo

Phapang e kholo e teng ka thepa e boletsoeng ea oli. Ho na le likarolo tse 'maloa tsa bohlokoa tsa sehlahisoa:

- viscosity, haholo-holo ho itšetlehile ka mocheso;

- durability ho boloka thepa, ke hore, durability;

- thepa ea detergent le dispersant, bokhoni ba ho arola lihlahisoa tsa tšilafalo le ho li boloka ho tsoa lintlha;

- acidity le ho hanyetsa ho bola, haholo ha oli e ntse e tsofala;

- boteng ba lintho tse kotsi, haholo-holo sebabole;

- tahlehelo ea likhohlano ka hare, bokhoni ba ho boloka matla.

Ho matha ka mafura a boima a nang le khatello e phahameng ea khatello ho thusa ho bokellana ha soot le sulfuric acid ka har'a crankcase. Boemo bona bo mpefatsoa ke ho ba teng ha turbocharging enjeneng e 'ngoe le e 'ngoe ea diesel ea baeti. Kahoo litaelo tsa tšebeliso ea oli e khethehileng, moo sena se nkoang ka har'a sephutheloana sa tlatsetso. Ho feta moo, ho fetola khafetsa joalo ka ha ho bokellana ha liaparo ho ke ke ha qojoa.

Oli e na le setsi sa motheo le sephutheloana sa tlatsetso. Ke tloaelo ho ahlola boleng ba sehlahisoa sa khoebo ka motheo oa sona. E ka ba liminerale kapa tsa maiketsetso. Ka motsoako o tsoakiloeng, oli e bitsoa semi-synthetic, le hoja hangata e le "metsi a liminerale" a bonolo a nang le tlatsetso e nyenyane ea metsoako ea maiketsetso. Tšōmo e 'ngoe ke molemo o feletseng oa li-synthetics. Leha e boetse e tsoa litsong tse fapaneng, lihlahisoa tse ngata tsa tekanyetso li entsoe ka lihlahisoa tse tšoanang tsa peterole ka hydrocracking.

Bohlokoa ba ho boloka palo e nepahetseng ea oli tsamaisong

Bakeng sa litsamaiso tse nang le bate ea oli ka har'a crankcase, boemo bo tlameha ho bolokoa ka har'a meeli e thata. Ho kopana ha enjene le litlhoko tsa tšebeliso ea moruo ea lihlahisoa tse theko e boima ha li lumelle ho thehoa ha li-pallets tse ngata. 'Me ho feta boemo bo tletse ka ho ama crankshaft crank ka seipone sa ho hlapa ka oli, se tla lebisa ho phophomang le tahlehelo ea thepa. Haeba boemo bo le tlase haholo, ho fetella ha lateral kapa ho potlakisa ha longitudinal ho tla lebisa ho pepeseheng ha moamoheli oa oli.

Li-motors tsa morao-rao li atisa ho ja oli, e amanang le tšebeliso ea li-skirts tse khutsufalitsoeng tsa piston, mehele e tšesaane ea ho boloka matla le ho ba teng ha turbocharger. Ka hona, haholo-holo ba hloka ho behoa leihlo khafetsa ka dipstick ea oli. Ho feta moo, li-sensor tsa boemo li kentsoe.

Enjene ka 'ngoe e na le moeli o behiloeng oa tšebeliso ea oli, e lekantsoeng ka lilithara kapa lik'hilograma ka lik'hilomithara tse sekete. Ho feta letšoao lena ho bolela mathata a ho roala ha li-cylinders, li-piston rings kapa litiiso tsa oli tsa li-valve stems. Mosi o hlokomelehang o tsoang tsamaisong ea ho ntša metsi o qala, ho silafala ha li-converter tsa catalytic le ho thehoa ha soot ka likamoreng tse tukang. Enjene e hloka ho fetoloa kapa ho fetoloa. Ho chesa ha oli ke e 'ngoe ea matšoao a mantlha a boemo ba enjene.