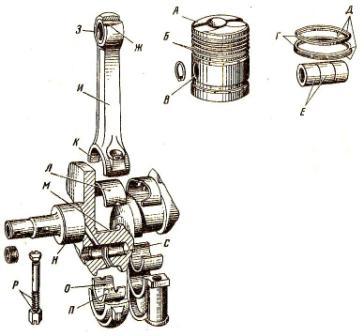

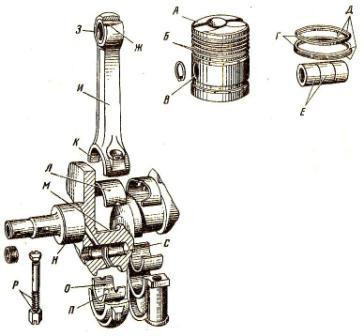

Tokiso ea molamu o kopanyang le piston kit

Litšitiso tse kholo tsa likarolo tsa molamu o kopanyang le piston li bonts'itsoe ho Setšoantšo sa 64.

Raese. 64. Litšitiso tse ka khonehang likarolong tsa molamu o kopanyang le piston kit.

A) - li-deposit tsa soot, coke, tar;

B) - ho roala groove;

B) - ho roala likoti bakeng sa menoana ka piston;

D) - ho roala holim'a bokantle ba mehele;

D) - ho roala ha mehele ka bophahamo;

E) - ho roala menoana ka ntle;

D) - ho apara seaparo sa ka ntle sa molamu o kopanyang;

H) - ho roala ha bushing ka hare ho molamu o kopanyang;

I) - Ho kobeha le ho hlekefetsoa ha molamu o kopanyang;

K) - ho apara ka hare ho hlooho e ka tlaase ea molamu o kopanyang;

L) - apara ka lehlakoreng le ka ntle la lesela;

M) - ho roala koranta ea molamu o kopanyang;

H) - Seaparo se seholo sa molala;

O) - ho apara ka lehlakoreng le ka hare la lesela;

P) - Ho senngoa ha ho kenngoa ha antenna;

P) - Ho phatloha le ho senngoa ha likhoele tsa li-bolts tsa molamu o kopanyang;

C) - Ho beha lihlahisoa tsa liaparo.

Piston ea piston e tsosolosoa ke ho atolosoa ha serame (plastic deformation) e lateloa ke phekolo ea mocheso, katoloso ea hydrothermal ka phekolo ea mocheso ka nako e le 'ngoe, mekhoa ea electroplating (chromium plating, hard iron). Ka mor'a ho tsosolosoa, lithakhisa tsa piston li sebetsoa ka mechine ea ho sila e se nang setsi 'me e bentšitsoe ka boholo bo tloaelehileng, ha boima bo holimo bo fihla ho Ra = 0,16-0,32 microns.

Nakong ea kabo ea hydrothermal, HDTV e futhumatsa monoana ka har'a inductor ho mocheso oa likhato tse 790-830 tsa Celsius, ebe e e pholisa ka metsi a phallang, e feta ka har'a sekoti sa eona se ka hare. Tabeng ena, monoana o thatafala, bolelele ba oona le bophara ba ka ntle bo eketseha ho tloha ho 0,08 ho ea ho 0,27 mm. Menoana e telele e fatše ho tloha lipheletsong, ebe li-chamfer li tlosoa ka ntle le ka hare.

Lihlahla tsa hlooho e ka holimo ea molamu o kopanyang. Li tsosolosoa ka mekhoa e latelang: mocheso oa zinc plating ka ts'ebetso e latelang; li-deposit ka molamu o kopanyang; compression lateloa ke sebopeho sa bokaholimo ba ka ntle ea theipi tšepe ka tjheseletsa electrocontact (botenya ba theipi ho tloha litšepe tlaase-carbon ke 0,4-0,6 limilimithara).

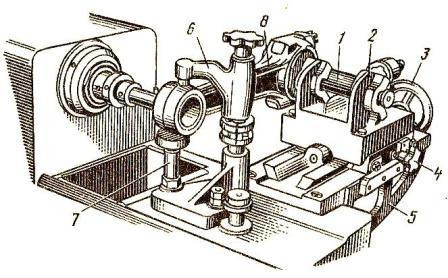

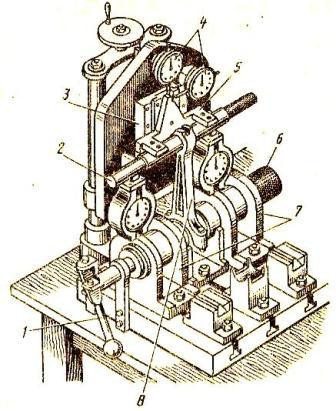

Molamu oa ho kopanya. Ha bokaholimo bo ka tlas'a sehlahla bo koaletsoe, molamu o kopanyang o phunngoa ho e 'ngoe ea boholo ba ho lokisoa ka nako ea 0,5 mm, e chamfering lipheletsong tsa 1,5 mm x 45 degrees. Bakeng sa boring, mochine oa ho cheka daemane URB-VP o sebelisoa, ho lokisa molamu o kopanyang [Setšoantšo sa mashome a tšeletseng a metso e mehlano].

Raese. 65. Ho tiisa molamu o kopanyang mochine ka ho phunya bushing ea hlooho e ka holimo.

1) - Ho lokisa;

2) - Li-prism tsa lipalangoang;

3) - Lebili la setere bakeng sa motsamao oa koloi;

4) - ho koala screw ea koloi;

5) - Tšehetso;

6) - Qhobosheane;

7) - Tšehetso;

- Molamu oa ho kopanya.

Mochine ona o ka phunya masoba ka bophara ba 28-100 mm ka lebelo la 600-975 min-1 le fepa ea 0,04 mm / rev.

Sebaka se pakeng tsa lilepe tsa lihlooho tse ka holimo le tse ka tlaase li finyelloa ka ho beha template pakeng tsa litopo tsa bracket (5) le koloi e tsamaeang. Ho nepahala ha ho kenngoa ha lesoba la molamu o kopanyang sefofaneng se otlolohileng se hlahlojoa ka sehahi 'me se lokisoe ka bracket (7).

Likarolo tse ka hare tse senyehileng tsa lihlooho tse ka tlaase le tse ka holimo tsa lithupa tse kopanyang mabenkeleng a ho lokisa li atolosoa ka electroplating, ho cheka le ho sila kapa ho bentša ho ea boholo bo tloaelehileng.

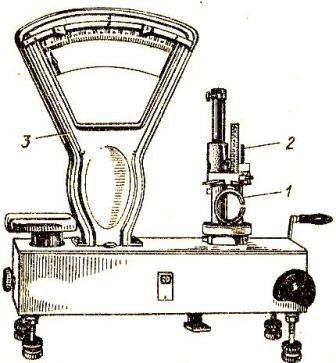

Ho fumana ho kheloha ho tloha ho parallelism (ho kobeha) ka lifofane tse otlolohileng le tse rapameng (torsion) tsa lilepe tsa hlooho e ka holimo e amanang le hlooho e ka tlaase holim'a lienjineri tsa carburetor, kopano ea molamu o kopanyang le sekoahelo e hlahlojoa sesebelisoa se khethehileng [ENG. 66], le bakeng sa motho e mong le e mong, letsetsa 70-8735-1025.

Raese. 66. Sesebelisoa sa ho lokisa lithupa tse hokahanyang tsa lienjineri tsa likoloi.

1) - sebetsana bakeng sa ho tlosa rolara;

2) - mandrel e nyenyane;

3) - litataiso tse thellang;

4) - sesupo;

5) - rocker;

6) - mandrel e kholo;

7) - Shelf;

- Molamu oa ho kopanya.

Ho kheloha ho tloha ho parallelism (ho kobeha) ha lilepe tsa lihlooho tse kholo tse hokelang ho lumelloa bakeng sa lienjineri tsa diesel:

D-50 - 0,18mm;

D-240 - 0,05mm;

SMD-17, SMD-18 - 0,15mm;

SMD-60, A-01, A-41 - 0,07mm;

YaMZ-238NB, YaMZ-240B - 0,08mm.

E lumelletsoe ho falla:

D-50 - 0,3mm;

D-240 le YaMZ-240NB - 0,08mm;

SMD-17, SMD-18 - 0,25mm;

SMD-60 - 0,07mm;

A-01, A-41 - 0,11 limilimithara;

YaMZ-238NB - 0,1mm.

Bakeng sa lienjineri tsa likoloi, ho kheloha ho tloha ho parallelism ea li-shaft ho lifofane tsohle ha ho lumelloe ho feta 0,05 mm ka bolelele ba 100 mm. Ho felisa sekoli sena, ho lumelloa ho otlolla lithupa tse kopanyang feela ka mor'a ho futhumatsa molamu oa bona ka mocheso o phahameng oa maqhubu kapa lelakabe la mollo oa khase ka mocheso oa likhato tse 450-600 tsa Celsius, ke hore, ka ho lokisa mocheso.

Pistons Tsosoloso ea li-piston tsa enjine ea diesel ea mofuta oa SMD e ka khoneha ka mokhoa oa plasma-arc surfacing. Ho etsa sena, piston e hloekisoa ka letsoai le qhibilihisitsoeng ka mocheso oa likhato tse 375-400 tsa Celsius ka metsotso e 10, e hlatsuoa, e tšoaroa ka 10% ea nitric acid ebe e hlatsuoa hape ka metsi a chesang ho tlosa li-varnish le li-deposit tsa carbon ka har'a li-grooves. Ka piston, groove e ka holimo le hlooho li lahleloa ka terata ea SVAMG le mochine.

Ho paka, kopano. Lihlopha tsa ho kopanya lithupa tse nang le li-caps, bots le linate li khethoa ka boima ho ea ka tafole 39.

Letlapa la 39

| Enjene e etsa | Phapang ea boima ba 'mele, g | ||

| melamu e hokahanyang | lipistone | ho kopanya melamu ka kopano ea piston | |

| A-01M, A-41 | 17 | mashome a mabeli | 40 |

| YaMZ-240B, YaMZ-238NB | 17 | 10 | mashome a mararo |

| SMD-14, SMD-62 le tse ling | 10 | 7 | 22 |

| D-240, D-50 | mashome a mabeli | 10 | mashome a mararo |

| D-37M | 10 | 10 | 25 |

| GAZ-53, ZIL-130 | 8 | 5 | leshome le metso e tšeletseng |

Ho tse ling tsa tsona, boima bo bontšoa karolong e ka ntle ea hlooho e ka tlaase, holim'a sekoahelo se bapileng le lesoba bakeng sa bolt ea molamu o kopanyang. Haeba ho hlokahala ho leka-lekanya boima, ho hlokahala ho kenya tšepe ea molamu o kopanyang haufi le moeli oa ho arohana ha litiiso ho ea botebo ba 1 mm.

Phapang ka bongata ba likarolo tsa kopano ea enjene nakong ea ts'ebetso ea eona e lebisa ho hlaha ha matla a inertia a sa leka-lekaneng, a bakang ho thothomela le ho potlakisa ts'ebetso ea ho roala likarolo.

Ka boima bo tšoanang ba molamu o kopanyang, kabo ea thepa ka bolelele e tlameha ho ba joalo hoo bongata ba lihlooho tse ka tlaase le tse ka holimo ka har'a molamu o kopanyang li lekana (phapang ha ea lokela ho feta ± 3 grams).

Li-piston li boetse li khethoa ka boholo le boima ba 'mele. Boima ba piston bo bontšoa ka tlase ho eona. Li-piston tse nang le matsoho li phethoa ho ea ka lekhalo pakeng tsa piston (haufi le seaparo) le sleeve, ho khetholla lihlopha tse nang le litlhaku tsa alfabeta ea Serussia (B, C, M, joalo-joalo), tse tlosoa ka tlase ho piston. lehetleng la letsoho.

Lithako tsa piston li khethoa ho ea ka boholo ba sehlopha sa masoba lihloohong tsa piston 'me li tšoauoa ka lipente kapa linomoro 0,1, 0,2, joalo-joalo.

Lihlahla ho ea ka bophara ba ka ntle li khethiloe ho ea ka bophara ba hlooho e ka holimo ea molamu o kopanyang, 'me ho ea ka bophara bo ka hare - ho ea ka bophara ba pini, ho nahanoa ka tumello ea ho sebetsa.

Li-liner li tlameha ho lumellana le bophara ba likoranta tsa crankshaft.

Mehele ea piston e khethiloe ho ea ka boholo ba li-liner le tumello ea piston groove, e lumelloang bakeng sa selikalikoe sa pele sa lienjiniere tsa diesel tsa YaMZ, A-41 le SMD-60 mefuta ea 0,35 mm (bakeng sa tse ling - 0,27). mm). Bakeng sa likarolo tsa khatello ea bobeli le ea boraro, lekhalo ke 0,30 mm le 0,20 mm, ka ho latellana.

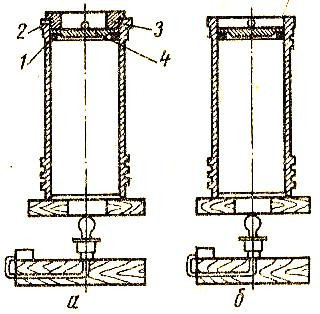

Elasticity ea mehele e hlahlojoa ka ho li beha hammoho sebakeng se otlolohileng sethaleng sa tekanyo e khethehileng ea MIP-10-1 [Feie. 67]. Reng e kenngoe ka mokhoa o tloaelehileng oa ho hlaka. Matla a bontšitsoeng ho daela ho leka-lekana a tlameha ho fihlela litlhoko tsa tekheniki.

Raese. 67. Ho hlahloba elasticity ea mehele ea piston ka sesebelisoa.

1) - Lesale;

2) - Sesebelisoa;

3) - Ponto.

Ho hlahloba ho tlosoa ha gasket, mehele ea piston e kenngoa ka har'a silinda ka thata ka sefofaneng se pota-potileng ho ea ho axis 'me e hlahlojoa ka sekhahla sa feeler. Boleng ba ho lekana ha mehele leboteng la cylinder leseling le bona bo hlahlojoa [Feie. 68].

Raese. 68. Ho hlahloba ho tlosoa ha mehele ea piston.

a) - Ho kenngoa ha reng,

b) - hlahloba;

1) - Lesale;

2) - Sleeve (cylinder ea tšehetso);

3) - Lesale la tataiso;

4) - Taelo.

Lekhalo mateanong a mehele e mecha bakeng sa dienjini tsa disele e lokela ho ba 0,6 ± 0,15 mm, e lumelletsoeng ntle le ho lokisoa - ho fihlela ho 2 mm; bakeng sa mehele e mecha ea enjene ea carburetor - 0,3-0,7 limilimithara.

Papali ea radial (backlash) lipakeng tsa selikalikoe le silindara bakeng sa lienjine tsa diesel ha ea lokela ho feta 0,02 mm libakeng tse fetang tse peli hammoho le li-arcs tsa likhato tse 30 mme e se haufi le 30 mm ho tloha senotlolo. Bakeng sa mehele ea torsion le conical, tumello ha e lumelloe ho feta 0,02 mm, bakeng sa mehele ea "scraper" ea oli - 0,03 mm kae kapa kae, empa e se haufi le 5 mm ho tloha senotlolo. Ho bapala ka meheleng ea lienjineri tsa carburetor ha ho lumelloe.

Ba boetse ba hlahloba bophahamo ba lesale le ho khopama ha libaka tsa ho qetela, tse sa lokelang ho feta 0,05 mm bakeng sa bophara ho fihlela ho 120 mm le 0,07 mm bakeng sa mehele ea bophara bo boholo.

kopano le taolo. Kopano ea molamu o kopanyang le piston kit e qala ka ho hatella lihlahla hloohong e ka holimo ea molamu o kopanyang ka ho kena-kenana le 0,03-0,12 mm bakeng sa lienjineri tsa dizeli tsa mefuta e fapaneng, 0,14 mm bakeng sa enjine ea carburetor. Molamu o kopanyang o kenngoa mochining oa ho phunya taemane oa URB-VP ka tsela e ts'oanang le e bontšitsoeng ho Setšoantšo sa 65, ebe bushing e phunngoa ka tumello:

ho pota-pota 0,04-0,06mm,

bakeng sa ho phethola ka 0,08-0,15 mm kapa ho tsosolosa ka 0,05-0,08 mm mabapi le bophara bo tloaelehileng ba phini ea piston.

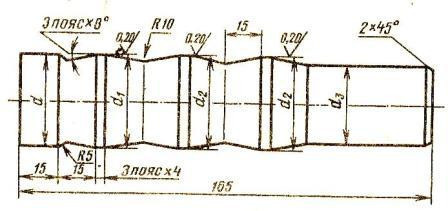

Lihlahla li pitikisoa ke ho phuphusela ha pulse mochining oa ho cheka o otlolohileng, o borehile tlasa mochini oa khatiso o tsamaisoang ka mochini o nang le phepelo e tsoelang pele ea mandrel [Feie. 69], e tlotsitsoeng ka mafura a diesel.

Raese. 69. Dorn ea bushing ea hlooho e ka holimo ea molamu o kopanyang.

d = D - 0,3;

d1 = D(-0,02/-0,03);

d2 = D(-0,09/-0,07);

d3 = D – 3;

D = piston piston bophara ba lebitso.

Joale ho kheloha ho tloha ho ts'oana ha lilepe tsa likoti tsa bushing le hlooho e ka tlaase ea molamu o kopanyang e laoloa ho ea ka litlhoko tsa theknoloji. Tabeng ena, ho hlophisa molamu oa ho kopanya ha ho lumelloe. Ka mor'a moo, hlooho e ka tlaase ea molamu o kopanyang e bokelloa ka lihlahla, sekoahelo le li-bolts. Liboutu li lokela ho kena ka likoti ka likotlo tse bobebe tse tsoang hamore ea 200-gram.

Likanale tsa oli tsa molamu tse kopanyang lia hlatsuoa ebe li hloekisoa ka moea. Li-piston li tlameha ho futhumatsoa ka har'a khabinete ea motlakase ea OKS-7543 kapa ka bateng ea metsi a oli ka mocheso oa likhato tse 80-90 tsa Celsius, ebe li kopanngoa le molamu o kopanyang ka piston ka piston.

Kopano e bokaneng e behiloe holim'a poleiti ea taolo e le hore piston e ama ntlha leha e le efe holim'a poleiti. Ka lekhalo le bōpehileng joaloka lekhalo le fetang 0,1 mm ka bolelele ba 100 mm (le lekanngoa ka probe), kit e a aroloa, likarolo li hlahlojoa, sekoli se tsejoa le ho tlosoa.

Piston ea li-piston tsa baokameli ba piston e ts'oaretsoe ka liloko tsa selemo. Pele o kenya mehele, hlahloba taper ea bokaholimo ba bona bo ka ntle holim'a poleiti ea taolo u sebelisa sekoere.

Mehele e kentsoe piston ka bophara bo nyane ho ea holimo (compression, undercut up) robeli *