Karolo: Tokiso - Ho Khanna Hantle, Setaele se Molemohali

Bakhanni ba bangata ba etsa qeto ea ho etsa liphetoho likoloing tsa bona e le hore ba ka ntlafatsa ponahalo ea bona le litekanyetso tsa tekheniki. Ketso tsena re li bitsa tokiso. Lentsoe tuning ka boeona le tsoa puong ea Senyesemane 'me le bolela phetoho, tokiso.

Bakhanni ba bangata ba etsa qeto ea ho etsa liphetoho likoloing tsa bona e le hore ba ka ntlafatsa ponahalo ea bona le litekanyetso tsa tekheniki. Ketso tsena re li bitsa tokiso. Lentsoe tuning ka boeona le tsoa puong ea Senyesemane 'me le bolela phetoho, tokiso.

Ho na le mefuta e 'meli ea mantlha ea tokiso - optical le mechanical. Optical tuning ke phetoho ea ponahalo.  ponahalo ea koloi ka ho kenya likarolo tse ling (mohlala, li-spoilers), ho fetola likarolo tsa feme ka likarolo tse nang le chebahalo e fapaneng (mohlala, mabone a siling a tint, mabili a alloy alloy) kapa varnish e ikhethang ea koloi. Ka lehlakoreng le leng, tokiso ea mochini ke phetoho methating ea ho khanna koloi (ho eketsa matla a enjene, ho ntlafatsa ts'ebetso ea sistimi ea braking, ho fetola liparamente tsa ho emisa).

ponahalo ea koloi ka ho kenya likarolo tse ling (mohlala, li-spoilers), ho fetola likarolo tsa feme ka likarolo tse nang le chebahalo e fapaneng (mohlala, mabone a siling a tint, mabili a alloy alloy) kapa varnish e ikhethang ea koloi. Ka lehlakoreng le leng, tokiso ea mochini ke phetoho methating ea ho khanna koloi (ho eketsa matla a enjene, ho ntlafatsa ts'ebetso ea sistimi ea braking, ho fetola liparamente tsa ho emisa).

Liphetoho ka ho sebetsa

Hajoale, ho na le sehlotšoana se ikhethileng sa tokiso ea elektroniki. E kenyelletsa liphetoho ho software ea balaoli ba elektroniki ho ntlafatsa ts'ebetso. Liphetoho tse ling li ka kenyelletsoa ho tokiso ea optical le ea mochini. Mohlala o motle oa sena ke mokhoa oa braking le li-discs haholo-holo.

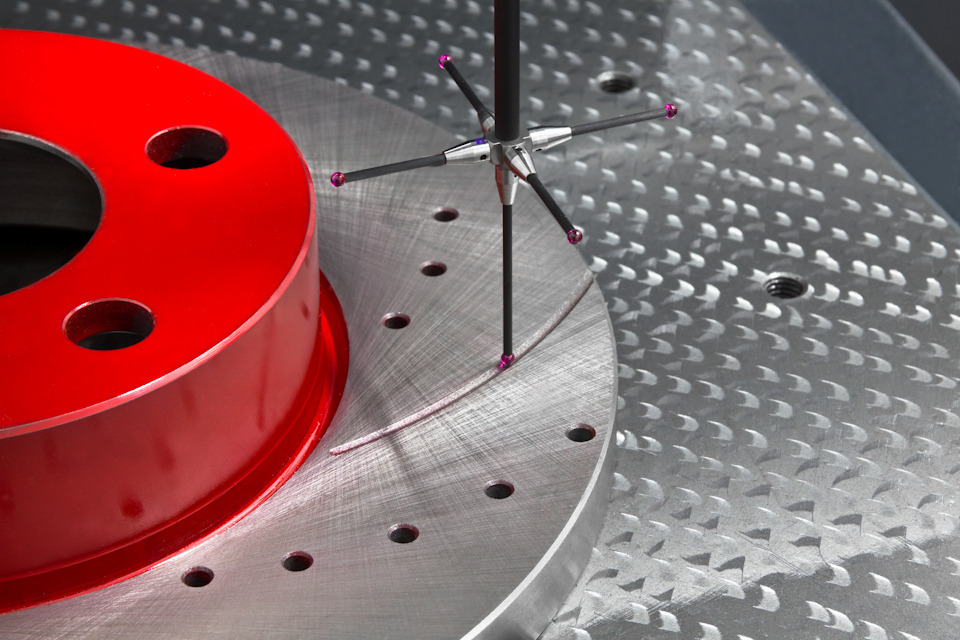

Ho fetola ponahalo ea li-brake discs ho finyelloa ka ts'ebetso e nepahetseng - ho itšeha, ho phunya, kapa ka bobeli. Tlhophiso e nepahetseng ea li-cutouts le masoba a phuntsoeng e fana ka litlamorao tsa pono ha koloi e eme le ha lebili le ntse le bilika butle. Mohlala oa sena ke likoti tse phuntsoeng tse bilikang ho ea pheletsong ea disc. Sistimi e joalo e fana ka maikutlo a matla ka ho sisinyeha le ho phomola. Ho fihlela phello e lakatsehang, li-discs tse nang le masoba a maholo li lokela ho sebelisoa ho bonts'a li-caliper le li-brake disc tse nang le moralo o motle oa litšoantšo.

Litlhahiso tse ngata le meralo

Ho na le bahlahisi ba bangata ba mabili a rekisoang 'marakeng oa likoloi, moo letoto la mabili a Rotinger Tuning le nang le botumo bo botle haholo. Li fanoa ka liphetolelo tse hlano. Har'a tsona ho na le li-drilled le slotted discs, hammoho le li-discs tse kopantsoeng ke masoba le li-slots. Haeba u thahasella lintlha, sheba lethathamo la lik'hamphani. Ena ke keletso e ntle le e sebetsang, kaha u tla khona ho nka lifahleho tsa oache tse nang le mohlala o u loketseng hantle. Ka mor'a ho li kenya, ntle le ho fetola ponahalo, re tla boela re ntlafatse litekanyo tsa tsamaiso ea braking. Lithebe tsena li kopanya litlamorao tsa pono le lipalo tse ntlafalitsoeng. Bakhanni ba rata likamano tsa mofuta ona. E tsamaea hantle, e shebahala e le betere.

U ka boela khetha motho ka mong tharollo le odara diseke ee ka ho feletseng motho ka mong mohlala oa masoba le slots. Ka tsela, re lemosa khahlanong le boiteko ba batho ba sa rutehang ba ho cheka kapa ho khaola li-discs. Sena se ka lebisa ho liketsahalo tse kotsi joalo ka: ho qhekella kapa esita le ho tlosoa ka ho feletseng ha disk drive.

Litekanyetso tse phahameng

Lithebe tsa moetsi enoa li tiisa tšireletso e feletseng, boemo ba setsebi ba tšebeliso le ponahalo e babatsehang. Ts'ebetso ea bona e etsoa ka mechini e nang le taolo ea linomoro. Sena se fella ka sehlahisoa se kopanang le maemo a thata bakeng sa axial runout le friction surface parameters. Ntle le machining a nepahetseng, ho bohlokoa hape hore li entsoe ka li-castings tse nang le khanyetso e eketsehileng ea mocheso. Ho latela melaoana ea hajoale ea EU, li-disk tsena li latela maemo a ECE R90 hape li tlas'a liteko tse fapaneng tse ikemetseng.

'Me qetellong, mantsoe a seng makae ka litšenyehelo. Bakeng sa ho lokisa mantsoe, hangata re khomarela sepache sa rona. Leha ho le joalo, litheko tsa lithebe li itšetlehile ka boholo ba tlhahiso le mahlale a sebelisoang. Li-rotingers tse hlahisitsoeng li na le litheko tsa demokrasi haholo. Hobane haeba khampani e e-na le phihlelo, e hlahisa haholo ka letoto 'me e na le sebaka se hlokahalang sa mochine bakeng sa tse nyenyane, tse se nang molekane, joale mokhanni ka mor'a chelete ea chelete a ke ke a kena-kenana.